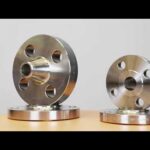

Most common weld neck flanges have standard bore or extra heavy bore. Sch 120 or Sch 160 bore flanges, in heavier weights such as 600# to 1500# are also common in weld neck flange. Trupply sells all kinds of weld neck flange in A105, A105N, Stainless Steel, Duplex and Super Duplex Steels and Nickel Alloys.

304 stainless steel flanges offer very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance. Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld. For technical drawings and 3-D models, click on a part number.

Weld Neck Flanges Class 150 attach to system via a circumferential weld at the neck. The welded area can be easily examined by radiography. Matched pipe and flange bore reduces turbulence and erosion inside the pipeline. Excellent in critical applications.

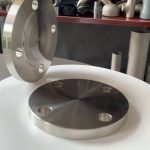

Stainless steel raised face weld neck flanges, are used to block the end of a pipe system or valve. The raised face is engineered to concentrate more pressure to a smaller area on the flange, which provides an increased containment capability at higher pressures.

Weld neck flange dimensions are covered in ASME B16.5 - which covers Pipe Flanges and Flanged Fittings for size NPS ½" to 24" for above NPS 26" to 60" it should be as per ASME B16.47. During a dimensional inspection of weld neck flange, you should check for. Outer & Inner Diameter of body; Bolt Circle & Bolt hole Diameter

304 stainless steel flanges offer very good corrosion resistance, and 316 stainless steel flanges have excellent corrosion resistance. Forged flanges have better strength than cast flanges. Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld.

We provide ANSI, API, and AWWA pipe flanges in carbon steel, stainless steel, alloys, and chrome steel. Styles we offer include Weld Neck, Slip On, Blind, Threaded, Socket Weld, Lap Joint, Orifice Flanges, Ring, and custom flanges in sizes from 1/2″ to 203″.

Weld Neck Flanges Class 150 attach to system via a circumferential weld at the neck. The welded area can be easily examined by radiography. Matched pipe and flange bore reduces turbulence and erosion inside the pipeline. Excellent in critical applications.

Reliable manufacturer of Stainless Steel 316 Flanges, Get price list of SS 316 Flanges, A182 F316 Slip On Flange, ASME SA182 SS 316 Weld Neck Flange, Check UNS S31600 Blind Flange Weight Chart Dimension. Call us at 91 22 6610 9925.

Website: https://www.emilymetal.com/

Email: [email protected]

Emily has an annual capacity of 10 million tons (of which 3.5 million tons are stainless steel). It can supply various special steel and stainless steel series products, including high quality cold-rolled coil/plate, hot-rolled coil/plate, hot-rolled medium plate, rod, seamless tube, welding tube, pipe fittings, flanges, profile steel, forgings and etc. It has several product clusters like stainless steel, special steel and high strength high ductility series that feature higher performance, energy efficiency and longer service life, which helps Emily stainless steel and special steel supplier with the fullest range of grades and specifications of products worldwide. We are the leading supplier of all steel material and related services for the world's energy industry and certain other industrial applications.